That's done! Your parts should now come out with the right sizes and things that are meant to fit together will too. The temp for the following layers should be lower and set so your printing object won't warp and lift coners or worse. Find a temp that allows good bonding but not as strong so you always have dismantle all to put the bed into the freezer to get your part off. ABS and other plastics won't bond to cold surfaces well but they also like to warp during the cooling. In this section we can also adjust the settings for our heated print bed if we have one. If you lines are too thin or the dimensions slightly too short you can incease the multiplier a bit. Once 20mm are reached on your object to match the 3D model you are good to go. After each change you do a test print again and measure. It is best to this in little steps, let's say from the above 1.1 to 1.0. So if your walls are too thick and the outside dimensions to big too you reduce the multiplier. "Extrusion Multiplier" is what adjusts the variations and tolerances of extruder, stepping and nozzle. I measured the filament to be 2.95mm in diameter so I adjusted this. (Calipers work great for this, a ruler might not be accurate enough) If the 200m cube turns out to be over 20mm on the outside and walls are thicker too it means you extrude too much filament. Use a slow speed to print it out and measure the outside dimensions. It is best to start with something simple and fast to print like a 20mm cube with slim walls and bottom.

#Prusa slic3r for mac download#

If you not already have some nice test objects fixed dimensions you can download a lot calibration models on Thingiverse. So adjust the above settings according to your nozzle diameter. The bridge flow rate is very important for the chewing "C" effect - I will come back to it. The overlap can be adjusted if you infill does not always fuse with the outer lines or simply looks too short.

This usually causes extreme amounts of plastic to be used during bridging and solid fills. As they also mess with calibrations we fix that now.īy default all settings are set to "0" and Slicer sometimes creates filling lines with 1.2 or more mm if not told to behave. One thing that Slicer is known be less than perfect is the problem of extrusion widths. I know there are certain file Slic3r simply does not slice right and some might require to use a different slicer for the job - this is not part of the Instructable.

#Prusa slic3r for mac how to#

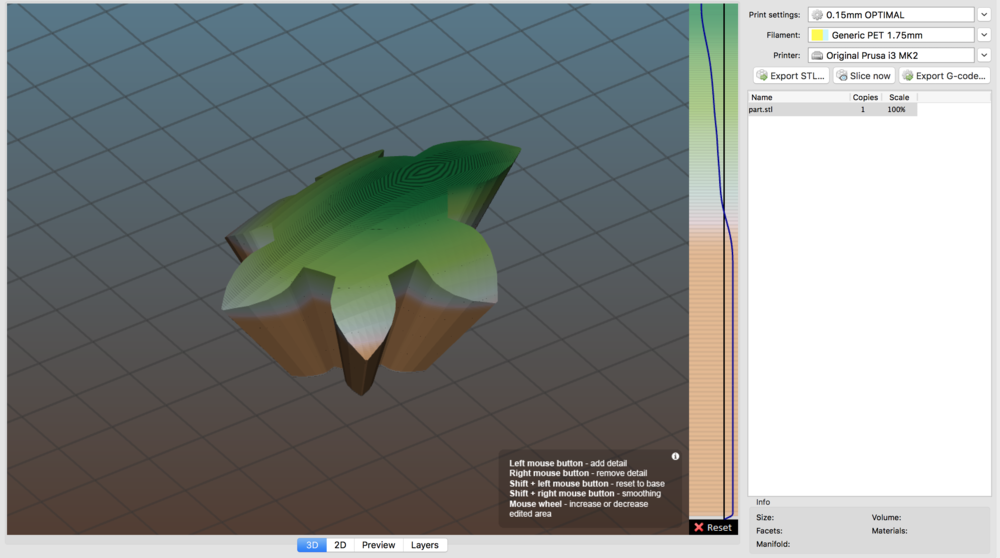

But the basics behind are the same and you will know after reading this Instructable how to get proper prints using Slic3r. For this tutorial I will assume a 0.7mm nozzle in all settings and 3.0mm filament - you have adjust to different settings accordingly. 3D printing is quite time consuming, so we neither want to spend time on messed up prints, nor on parts that do not match the dimensions of the 3D file. Maybe you printer works just fine but certain things suffer from drooping? Like when printing small parts that loose form while you print?Īny of that usually comes down to the often confusing settings in Slic3r, so I will try to show you where you have to be careful, what settings cause problems and so on.īefore we even start messing finetuning we should assume the printer hardware is calibrated and the same is true for the firmware. You ever had the problem that your extruder is chewing a nice C into your filament, especially somewhere in the middle of the print? Or your printer is perfectly calibrated in the hardware and firmware but your prints never match the dimensions of the part? (can be a pain to get a 8mm bolt through a 8mm hole if the printer messed up LOL) There are plenty of them around but today I will only focus on Slic3r as it is one of the most used programs for the job. When it comes to using your favourite toy to print some nice things we all need to use certain programs to generate the so called " G-Code".

#Prusa slic3r for mac update#

Update : Updated the step for the print settings for fixing prints that run out of alignment during printing. Update : Added a short video in the last step showing my Model T prusa running after optimisation at 70mm/s - if my printer can do this a modern one should be able to do it even faster.

0 kommentar(er)

0 kommentar(er)